Contact Us

MG-Hydro

Spółka z ograniczoną

odpowiedzialnością Sp.k.

Międzychodzka 14/33

60-371 Poznań

NIP 7792343037

REGON 300917611

Tel.: +48 61 861 44 58

Fax: +48 61 861 41 62

E-mail: office@mg-hydro.pl

Cornice board - Technical Approval IBDiM

Zestaw prefabrykatów gzymsowych MG-Hydro

W skład zestawu prefabrykatów gzymsowych MG-Hydro wchodzi:

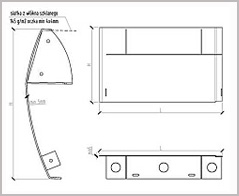

Cornice Prefabricate "MG-Hydro (Fig.1.) - a basic element of the facade of buildings bridge

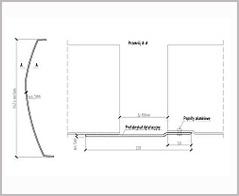

Prefabrication keep an expansion gap "MG-Hydro (Fig.2) - complementary to the elevation of the bridge, depending on the length of the construction and building bridges

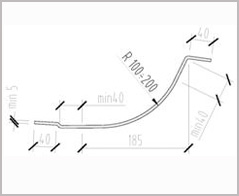

Prefabrication Shielding "MG-Hydro (Fig.3) - the item to cover the installation of cable and fittings carried out under the bridge structure

All elements forming part of set included in the set of prefabricated gzymsowych MG-Hydro are manufactured from polyester-glass laminate with a thickness of not less than 4 mm. Dimension "x" shown in Figures 1 and 2.

Prefabricated cornice MG-Hydro are produced in different dimensions "H" and "L", a different distribution of reinforcing ribs of various shapes and profiles.

The scope of the proposed footprint cornice prefabricate elevation:

Cornice prefabricate height from 600 to 1000 mm

Length cornice prefabricate 1000 to 2000m

Sample elevation of 1 item depending on size:

| Wysokość H [mm] | Grubość ścianki g [mm] | Długość elementu L [mm] | Masa [kg] |

| 600 | 5 | 1000 | 8,5 |

| 600 | 5 | 2000 | 16,0 |

| 700 | 5 | 1000 | 10,0 |

| 700 | 5 | 2000 | 18,5 |

| 1000 | 5 | 1000 | 14,5 |

| 1000 | 5 | 2000 | 23,0 |

Prefabricated cornice MG Hydro produced based on polyester-glass laminate (PWS) are composed of polyester resin, and cut a continuous glass fiber, fillers and additives appropriate to the production technology (PWS).

Outer surfaces of elements (the nonadjacent concrete) are covered by resin gel coat in any color according to RAL (under contract).

It is possible to paint prefabricated polyurethane paint after roughened surface and degreased.

Conglomerates are resistant to damage from impact. In the event of damage you can repair them.

Conglomerates are resistant to temperatures of both negative and positive from-40oC to +100 oC

Purpose and Scope

Elements of the bridge - Precast cornice MG Hydro - are designed to protect the bridge of concrete elements, steel and reinforced concrete, against the destructive action of chemically active aqueous solutions. May also be lost formwork for forming pavements, and the channels included in the drainage system.

Within the bridge expansion joints shall keep an expansion gap Prefabrication MG Hydro. In addition, in order to shield carried on the cable casing pipes (telecommunication, lighting, etc.) can be used Prefabrication Shielding Hydro MG.

The object of a bridge should be equipped in a "pre-cast cornice MG Hydro for the construction project done by authorized persons. If the proposal does not include technical specifications or technical requirements, the manufacturer of cornice prefabricated provide customers own technical specification, which describes how the cornice prefabricated assembly.

Prefabricated cornice MG-Hydro are designed so that combining them with concrete construction is achieved by use - tailored for this purpose - the construction elements and adhesive polyester-glass laminate mortar PC or PCC.

Cornice prefabricated facade elements in their design are:

- Ribs and rack assembly and are suitable for use reinforcing bars and anchor bolts.

Ornamental elements and shielding installations carried out under the bridge bracket plates are secured with anchor bolts and rivets break unilateral.

Prefabricated cornice MG Hydro should be fastened together with bolts stainless, galvanized screws or by bonding resin glue.

Installation of cornice prefabricated (elevation) is performed without the use of scaffolding and without heavy equipment. Prefabricate mass allows you to run assembly by two people.

Supplementary materials whose purpose and use the result of a construction project must comply with relevant standards or ETA to the extent specified in the building project.

If the laminate elements are pasted in construction using mortar PC or PCC must be observed for the mortar requirements for surface preparation and weather conditions during the exercise works.

All rights reserved: MG Hydro Sp. z o.o. Sp. k.

Code & Design: ic.online agencja interaktywna | XHTML 1.1